Choosing the Right Vibrating Screen Supplier: Key Considerations and Benefits

Introduction

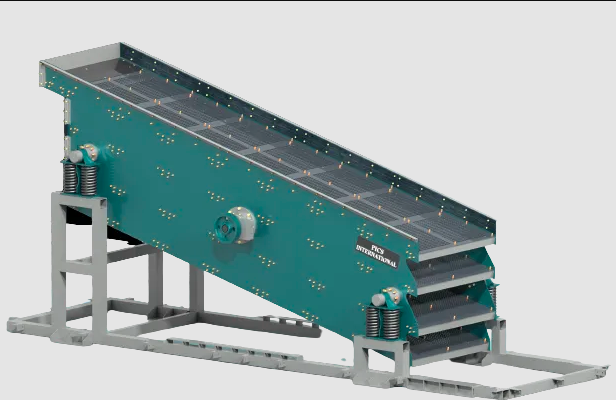

In various industrial applications, vibrating screens are essential for sorting and separating materials based on size and type. Whether in mining, construction, or manufacturing, the efficiency of these processes heavily relies on the quality of the vibrating screens used. Selecting the right Vibrating Screen Supplier is crucial for ensuring optimal performance, reliability, and support. This article explores the factors to consider when choosing a vibrating screen supplier, the benefits of partnering with a reputable supplier, and key considerations for making an informed decision.

1. Understanding Vibrating Screens

Vibrating screens are mechanical devices designed to separate and classify materials through vibration. They use screens or mesh to sort particles based on size, allowing for efficient processing of bulk materials. Common types of vibrating screens include linear, circular, and elliptical screens, each suited to different applications and material types.

2. Key Factors to Consider When Choosing a Vibrating Screen Supplier

2.1 Experience and Reputation

One of the first factors to consider is the supplier’s experience and reputation in the industry. A supplier with a proven track record of delivering high-quality vibrating screens and exceptional customer service is more likely to provide reliable and effective solutions. Research customer reviews, case studies, and industry testimonials to gauge the supplier’s reputation.

Read also: Proven Techniques to Soundproof Your Windows and Doors in Melbourne

2.2 Product Quality and Range

Evaluate the quality and range of vibrating screens offered by the supplier. A reputable supplier should provide high-quality screens made from durable materials such as stainless steel or high-carbon steel. Additionally, they should offer a variety of screen types and sizes to meet different application needs. Check if the supplier can provide customized solutions based on your specific requirements.

2.3 Technical Expertise and Support

Technical expertise is crucial when selecting a vibrating screen supplier. The supplier should have a team of knowledgeable engineers and technicians who can assist with product selection, installation, and troubleshooting. Comprehensive technical support ensures that you receive the right vibrating screen for your application and can address any issues that arise during operation.

2.4 Innovation and Technology

Consider the supplier’s commitment to innovation and technology. A supplier that invests in research and development is more likely to offer advanced vibrating screen technologies that improve performance, efficiency, and durability. Look for suppliers who offer modern features such as adjustable vibration settings, wear-resistant materials, and energy-efficient designs.

2.5 Customer Service and Support

Exceptional customer service and support are essential for a positive supplier relationship. Choose a supplier known for its responsive and helpful customer service team. They should be available to assist with inquiries, provide technical support, and offer after-sales services such as maintenance and repair.

2.6 Delivery and Lead Times

Assess the supplier’s delivery and lead times to ensure they align with your project schedules. A reliable supplier should be able to provide timely delivery of vibrating screens and meet agreed-upon deadlines. Delays in delivery can impact your operations, so it’s important to choose a supplier with a proven track record of on-time deliveries.

2.7 Cost and Value

While cost is a significant factor, it should not be the sole consideration. Evaluate the overall value provided by the supplier, including product quality, support, and additional services. A higher initial investment in a high-quality vibrating screen from a reputable supplier may result in lower long-term costs due to increased durability and reduced maintenance needs.

3. Benefits of Partnering with a Reputable Vibrating Screen Supplier

3.1 Reliable Performance

Partnering with a reputable vibrating screen supplier ensures that you receive high-quality products designed for reliable performance. High-quality screens perform efficiently and consistently, reducing downtime and enhancing productivity.

3.2 Customized Solutions

Reputable suppliers offer customized solutions to meet your specific needs. Whether you require screens for unique materials or specialized applications, a reliable supplier can provide tailored solutions to achieve optimal results.

3.3 Technical Support

A supplier with strong technical expertise provides valuable support throughout the product lifecycle. From selecting the right screen to troubleshooting issues, their expertise helps ensure smooth operation and resolves any challenges you may encounter.

3.4 Long-Term Cost Savings

Investing in high-quality vibrating screens from a reputable supplier can lead to long-term cost savings. Durable screens require less frequent replacement and maintenance, reducing overall operational costs and enhancing the return on investment.

4. How to Evaluate Potential Vibrating Screen Suppliers

4.1 Request Proposals and Quotes

Contact multiple suppliers to request proposals and quotes. Compare their offerings, including product specifications, pricing, and additional services. This comparison helps you make an informed decision based on your specific requirements and budget.

4.2 Visit Supplier Facilities

If possible, visit the supplier’s facilities to assess their manufacturing processes and quality control measures. A visit provides insight into their capabilities and helps ensure that they meet industry standards.

4.3 Check References

Request references from the supplier and contact their previous clients to gain feedback on their experiences. References provide valuable information about the supplier’s performance, reliability, and customer service.

Conclusion

Choosing the right vibrating screen supplier is a critical decision that impacts the efficiency and effectiveness of your material processing operations. By considering factors such as experience, product quality, technical expertise, and customer support, you can partner with a supplier who meets your needs and provides reliable, high-quality vibrating screens. Investing time in evaluating potential suppliers ensures that you make an informed choice, ultimately leading to improved performance, reduced costs, and successful outcomes for your projects.