Cobot Application in Welding, Packaging, and Assembly Explained

A cobot application is transforming industries by making processes like welding, packaging, and assembly faster, safer, and more efficient. Designed to work side by side with human workers, collaborative robots (cobots) handle repetitive or precision-based tasks with accuracy while reducing strain on employees.

From streamlining production lines to improving workplace safety, cobot applications are becoming essential tools in modern manufacturing. In this article, we’ll explain how cobots are used in welding, packaging, and assembly, and why they’re shaping the future of industrial automation.

What Is a Cobot?

A cobot application means using a collaborative robot (cobot) in real work environments to assist human workers. Cobots are designed to work safely alongside people, enhancing their abilities rather than replacing them. Unlike traditional industrial robots that work alone, cobots interact directly with humans to handle repetitive, dangerous, or physically demanding tasks. They include safety features like force sensors and soft materials to make collaboration safe.

How Cobots Are Transforming Modern Manufacturing

Collaborative robots (cobots) are revolutionizing manufacturing by blending automation with human expertise. They enhance productivity, safety, and flexibility, making them valuable across industries.

Enhanced Safety and Collaboration

Cobots are built to work safely alongside humans without protective cages. Using advanced sensors and force-limiting technology, they detect human presence and react instantly, reducing accident risks. This enables seamless human-robot teamwork and fosters a safer, more inclusive workplace.

Cost-Effectiveness and Fast ROI

Cobots are cost-effective because they are less expensive than traditional industrial robots and require minimal infrastructure. Their simple setup and programming enable fast deployment, often delivering a return on investment within a few months, which makes them especially suitable for small and medium-sized enterprises (SMEs).

Flexibility and Adaptability

Cobots are highly versatile and can be quickly reprogrammed for different tasks. This flexibility suits dynamic production environments or high-mix, low-volume manufacturing. They switch tasks with minimal downtime, keeping operations efficient.

Improved Quality and Precision

Cobots use advanced sensors and vision systems to work precisely and consistently, reducing defects and waste. In tasks like assembly, welding, and inspection, they often outperform humans in repetitive work.

Empowering Human Workers

Cobots handle repetitive, dangerous, or physically demanding tasks, allowing humans to focus on complex, creative, and high-value work. This boosts productivity and job satisfaction, fostering a more skilled and motivated workforce.

Cobots combine automation with human collaboration to make manufacturing safer, more efficient, and more adaptable. Their affordability, precision, versatility, and ability to empower workers make them essential for modern production. As industries evolve, cobots will continue to drive innovation and help businesses stay competitive.

See also: Exploring the Role of Secyvimeo in Technological Advancements

Cobot Application in Welding

Collaborative robots (cobots) are revolutionizing welding by enhancing precision, safety, and overall quality. Here’s how they make a difference:

Precision Welding

Cobots perform precise and consistent welding, keeping the weld path within 0.02mm. This reduces human error, ensures uniform welds, and minimizes defects.

Enhanced Worker Safety

Cobots improve safety in welding by handling the most dangerous tasks, reducing workers’ exposure to heat, fumes, and intense light.

Superior Weld Quality

Cobots ensure high-quality welds by maintaining consistent parameters, reducing defects, minimizing rework, and increasing efficiency.

Cobots make welding safer, more accurate, and more reliable. Their ability to improve weld quality and minimize errors makes them indispensable in modern manufacturing.

Cobot Application in Packaging

Cobots are transforming packaging and palletizing for SMEs by improving efficiency, safety, and flexibility.

Automating Repetitive Tasks

Cobots handle repetitive tasks like picking, packing, and stacking products, performing them with high precision to reduce errors and increase efficiency. Tasks such as box erecting and palletizing can be automated quickly, often paying off the investment within about a year.

Reducing Worker Strain and Accelerating Logistics

Cobots reduce physical strain on workers by handling heavy lifting and repetitive stacking. They work continuously without fatigue, ensuring consistent performance and speeding up logistics processes while lowering the risk of injuries.

Flexible and Adaptable

Cobots can be easily reprogrammed to handle different products and packaging formats. This adaptability makes them ideal for SMEs that frequently switch product lines or packaging styles, ensuring minimal downtime and faster responses to market demands.

Cobots help SMEs automate packaging and palletizing, protect workers, and adapt to changing products, making them essential for efficient and flexible manufacturing.

Cobot Application in Assembly

Collaborative robots (cobots) are improving assembly work by helping with repetitive or detailed tasks. They ensure accuracy, reduce errors caused by fatigue, and make production lines more efficient.

Assisting with Repetitive or Detailed Tasks

Cobots perform repetitive or detailed tasks such as tightening screws, applying adhesives, or placing components with consistent accuracy. This minimizes errors, supports key industries, and lets humans focus on more complex tasks, boosting overall productivity.

Improving Accuracy and Reducing Errors

Cobots perform tasks with high precision, lowering the chances of mistakes and product defects. Studies show that production output can increase by nearly 24% when cobots assist in assembly, thanks to their consistency and reliability.

Enhancing Efficiency and Supporting Workers

Working alongside humans, cobots take on repetitive or physically demanding tasks. This speeds up assembly, reduces worker strain, and improves job satisfaction. Cobots are also easily reprogrammable, allowing them to adapt to different products or production changes, providing flexibility and scalability.

Cobots in assembly lines improve precision and speed by performing repetitive tasks. This lets human workers focus on more complex jobs, making the entire manufacturing process more effective and successful.

Cobots Application in Manufacturing

Cobots are transforming manufacturing by easily integrating into production lines, improving precision, consistency, and productivity without major infrastructure changes.

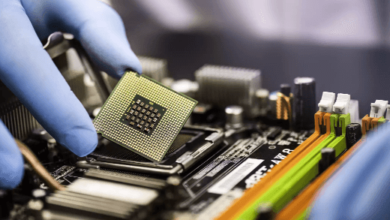

- Precision Assembly and Placement

Cobots handle tasks that need careful positioning and assembly, such as placing components on circuit boards or assembling mechanical parts. They work consistently without fatigue, making them ideal for production that requires both flexibility and accuracy. - Accurate Tool Handling

Cobots handle tools with precision and stability in industries like electronics and medical devices. They perform tasks such as gluing, fastening, or screwing consistently over thousands of cycles, ensuring reliable and high-quality products. - Consistent Finishing

Cobots perform finishing tasks such as sanding, polishing, painting, and welding with steady pressure and precise movements. This ensures high-quality results while keeping workers safe from dust, fumes, and repetitive strain injuries.

The International Federation of Robotics reports that cobots boost efficiency and product quality in automotive, electronics, and metal industries. Beyond automation, they help manufacturers meet growing demands for speed and precision in a competitive market.

Conclusion: The Transformative Impact of Cobots in Manufacturing

Collaborative robots (cobots) are revolutionizing manufacturing processes across welding, packaging, and assembly by enhancing productivity, safety, and adaptability. Their ability to work alongside human operators allows businesses to automate repetitive tasks, reduce error rates, and improve overall efficiency.

Cobots’ flexibility makes them suitable for various applications, enabling manufacturers to scale operations without significant capital investment. As industries evolve, cobots are becoming important in automation, helping businesses work more efficiently and stay competitive around the world.